Thermal Insulation Coating +

Scoat™ Thermal Insulation Coating+ (TIC+) is an ultimate thermal insulation coating engineered specifically for the demanding conditions of the marine sector. Designed to provide superior insulation properties while effectively preventing condensation and mould formation, Scoat™ TIC+ sets a new standard for marine insulation solutions.

PRODUCT NAME

THERMAL INSULATION COATING +

BASE

WATER BASED ACRYLIC COATING

CONTAINER SIZE

18 LITRES

Description

Scoat™ Thermal Insulation Coating+ (TIC+) is an ultimate thermal insulation coating engineered specifically for the demanding conditions of the marine sector. Designed to provide superior insulation properties while effectively preventing condensation and mould formation, Scoat™ TIC+ sets a new standard for marine insulation solutions.

It improves efficiency and cost-effectiveness for ship operators by minimising energy consumption through the reduction of heat transmission.

However, Scoat™ TIC+ is more than just insulation. Because of its unique formulation, it provides a strong barrier against moisture infiltration, which is essential for surviving the harsh maritime climate that is infamous for its high humidity and exposure to seawater.

Scoat™ TIC+ reduces the possibility of corrosion, mould, and mildew by preventing condensation from collecting on surfaces, protecting the equipment and vessel structures. Likewise, the coating effectively addresses long-standing problems related to condensation control, safe contact, and energy efficiency by adhering to the substrate surface and significantly lowering the likelihood of corrosion under insulation (CUI).

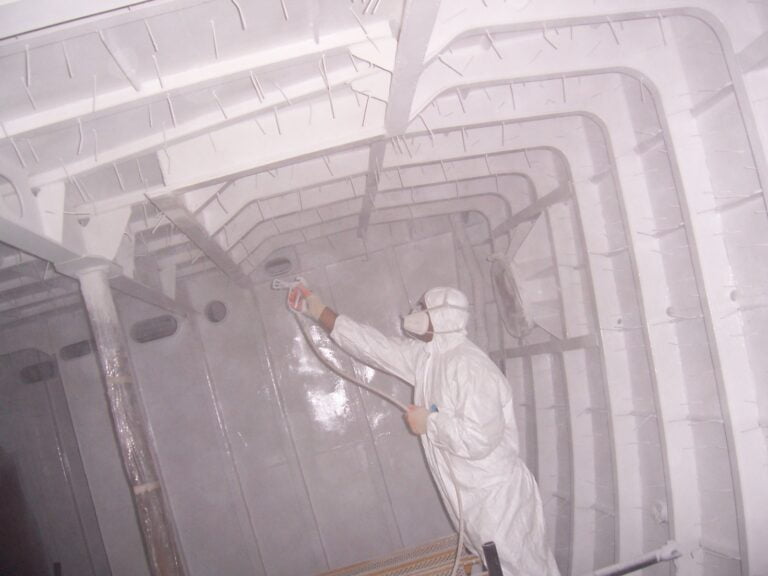

When used on ship hulls, cargo holds, engine rooms, or bulkheads, Scoat™ TIC+ offers the best protection and functionality available. Its robust, weather-resistant coating can handle the rigours of maritime operations and offers all sizes and types of vessels long-lasting insulation and moisture management.

Surfaces to Apply

Ship Hulls: Applying coatings to the interior hull of ships helps reduce heat absorption from the sun, enhance energy efficiency, and prevent condensation that can lead to corrosion.

Bulkheads: Internal bulkheads benefit from these coatings by improving thermal insulation, reducing heat transfer between compartments, and preventing condensation, which can cause rust and structural damage.

Ceilings: Coatings on ceilings in cabins and common areas improve thermal comfort, reduce energy costs, and prevent condensation that can lead to mould and mildew.

Pipes and Ductwork: Insulating pipes and ductwork helps maintain temperature consistency within HVAC systems, improves energy efficiency, and prevents condensation that can lead to water damage and corrosion.

Engine Rooms: Applying coatings to surfaces in engine rooms helps manage heat generated by machinery, improves energy efficiency, and prevents condensation that can affect equipment performance and safety.

Storage Tanks: Coating storage tanks for fuel, water, or other liquids helps maintain temperature stability, reduces energy costs, and prevents condensation, which can lead to contamination and corrosion.

Cabin Walls: Applying coatings to the walls of cabins helps maintain a comfortable interior temperature, enhances energy efficiency, and prevents condensation that can affect the living environment.

Control Rooms: Control rooms benefit from these coatings by maintaining stable temperatures for sensitive equipment, improving operational efficiency, and preventing condensation that could damage electronics.

Galley Areas: In kitchens and food preparation areas, coatings help manage heat, maintain a hygienic environment, and prevent condensation that can lead to mould and mildew.

Ventilation Shafts: Insulating ventilation shafts improves air quality and temperature control within the ship and prevents condensation that can cause rust and reduce system efficiency.

These surfaces in the marine industry benefit significantly from the application of thermal insulation and anti-condensation coatings, enhancing energy efficiency, protecting against moisture-related damage, and improving overall operational safety and comfort.

Technical Data

1 | Base | Water based acrylic coating |

2 | Container size | 18 litres |

3 | Weight dry | 0.34 kg/m2 at 1mm |

4 | Weight wet | 0.74 kg/litre |

5 | Container wet | 13.32 kg |

6 | Coverage (per litre) | 1.0 m2 at 1.00 mm DFT |

7 | Top coating | Please contact us for more information |

8 | Solid content | 78-81% |

9 | Limitations | Applications should not exceed 185°C. |

10 | Surface temperature | Surface temperatures for applications should be greater than 5°C. |

11 | Method of application | Airless spray, Small spray application, Brush or roll |