Thermal Insulation Coating

Introducing Scoat™ Thermal Insulation Coating (TIC), the greatest moisture management and thermal insulation solution. Our revolutionary coating combines moisture resistance technology with cutting-edge thermal insulation capabilities to provide unparalleled protection against condensation and mould growth. This coating solves long-standing issues with energy efficiency, safe contact, and condensation control by sticking to the substrate surface and thereby greatly reducing the probability of corrosion under insulation (CUI).

PRODUCT NAME

THERMAL INSULATION COATING

BASE

WATER BASED ACRYLIC COATING

CONTAINER SIZE

18 LITRES

Description

Introducing Scoat™ Thermal Insulation Coating (TIC), the greatest moisture management and thermal insulation solution. Our revolutionary coating combines moisture resistance technology with cutting-edge thermal insulation capabilities to provide unparalleled protection against condensation and mould growth. This coating solves long-standing issues with energy efficiency, safe contact, and condensation control by sticking to the substrate surface and thereby greatly reducing the probability of corrosion under insulation (CUI).

Scoat™ TIC is made of cutting-edge insulating materials that effectively reduce heat transfer, keeping rooms warmer in the winter and colder in the summer. It serves to create a steady and comfortable climate while drastically cutting down on energy use and utility expenses by erecting a barrier against outside temperature swings.

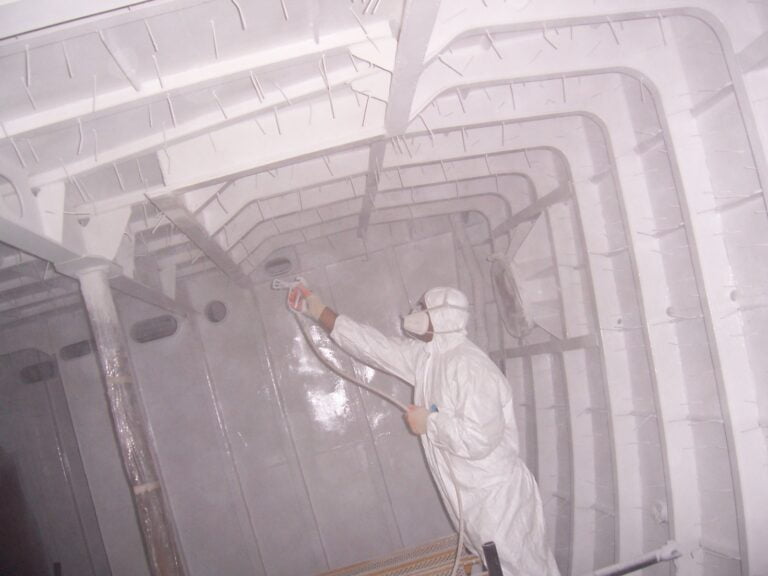

Scoat™ TIC provides exceptional performance and long-lasting results when applied to walls, ceilings, roofs, or any other surface that requires insulation and moisture protection. Because of its versatility and ease of application, it is the greatest choice for areas that are commercial, industrial, and residential.

For many thermal insulating coating applications over machinery, such as pipes, pipelines, tanks, ovens, processing vessels, heat exchangers, and more, these coatings are the best option available. By combining corrosion control and insulation into one solution, Scoat’s revolutionary industrial thermal insulation coating avoids corrosion-under-insulation (CUI).

Typical Uses

Scoat™ Thermal Insulation Coating is highly adaptable and have uses in a variety of environments and industries.

1.Residential Buildings: To enhance energy efficiency, control interior temperature, and avoid moisture accumulation in humid regions, these coatings can be used on external walls, roofs, and attics in residential construction. Additionally, they prevent mould growth, improving the health of occupants and the purity of indoor air.

2.Commercial Buildings: Thermal insulation coatings help offices, stores, and other commercial premises keep pleasant interior temperatures, cut down on energy bills for heating and cooling, and minimise moisture-related problems like condensation on walls and windows. For both clients and staff, this fosters a more salubrious and effective work atmosphere.

3.Industrial Facilities: Temperature control and moisture management are common problems in factories, warehouses, and manufacturing plants. Thermal insulation coatings reduce heat loss, stop condensation on machinery and surfaces, and guard against mould and corrosion growth in moist situations by applying them to structural parts, pipes, and equipment.

4.Cold Storage Facilities: To maintain low temperatures and avoid energy waste, refrigerated warehouses and cold storage facilities need to have adequate thermal insulation. In addition to lowering the risk of mould and bacterial growth, coatings with moisture protection qualities assist avoid condensation inside storage units, maintaining the freshness and quality of perishable goods.

5.Transportation: To ensure that temperature-sensitive items are kept at the proper temperature while in transit, thermal insulation coatings are used in the transportation sector to insulate cargo holds, shipping containers and refrigerated trucks. These coatings help minimise product loss and maintain the integrity of the cargo by avoiding condensation and mould formation.

6.Food Processing Facilities: To keep production spaces clean, control temperatures, and avoid moisture-related problems, food processing and packaging facilities rely on thermal insulation coatings. These coatings help ensure adherence to food safety laws and guard against contamination hazards brought on by the growth of mould and mildew.

7.HVAC Systems: Applying thermal insulation coatings to HVAC equipment and ductwork can increase energy efficiency, lower heat transfer losses, and stop condensation from forming inside the system. These coatings work to reduce moisture buildup, which inhibits microbial growth and increases the longevity of HVAC components.

Other Applications

1.Automotive Industry: These coatings can be used in vehicles to insulate engine compartments, reduce heat transfer, and prevent condensation on metal surfaces, improving the longevity and efficiency of vehicle components.

2.Oil and Gas Industry: In the oil and gas sector, these coatings are used on pipelines, storage tanks, and processing equipment to provide thermal insulation, reduce energy costs, and prevent condensation that could lead to corrosion and operational issues.

3.Electronics and Server Rooms: Applying these coatings in server rooms and on electronic equipment helps maintain optimal operating temperatures and prevents condensation, which can cause electrical failures and equipment damage.

4.Food and Beverage Industry: Thermal insulation coatings are used on tanks, pipes, and processing equipment to maintain temperature control, prevent condensation, and ensure hygiene and safety in food production and storage areas.

5.Sports and Leisure Facilities: Indoor swimming pools, ice rinks, and other sports facilities use these coatings to manage temperature and humidity levels, preventing condensation and maintaining a comfortable environment for users.

6.Aerospace Industry: Aerospace components and structures benefit from these coatings to manage thermal loads, improve energy efficiency, and prevent condensation, which can impact both performance and safety.

7.Power Generation Plants: Thermal insulation coatings are applied to boilers, turbines, and other equipment in power plants to enhance thermal efficiency, reduce energy losses, and prevent condensation-related corrosion.

8.Heritage and Historic Buildings: These coatings can be used to insulate and protect historic buildings, maintaining internal temperature stability while preventing condensation that can damage delicate structures and finishes.

These additional applications highlight the versatility and broad utility of thermal insulation coatings with anti-condensation properties across various fields and industries.

Surfaces to Apply

1.Walls: Both interior and exterior walls of buildings can benefit from these coatings to improve thermal insulation and prevent condensation, enhancing overall energy efficiency.

2.Ceilings: Applying coatings to ceilings helps reduce heat transfer and prevent condensation, contributing to a more comfortable indoor environment.

3.Roofs: Coatings on roofs help to reflect heat, reduce cooling costs, and prevent condensation, which can lead to leaks and structural damage.

4.Floors: Basements and ground floors can be treated to prevent heat loss and condensation, improving thermal comfort, and protecting against moisture-related issues.

5.Pipes and Ductwork: Coatings applied to pipes and HVAC ductwork help maintain temperature, reduce energy loss, and prevent condensation that can cause water damage.

6.Tanks and Storage Vessels: These surfaces, particularly in industrial settings, benefit from insulation to maintain temperature stability and prevent condensation, which can lead to corrosion.

7.Metal Structures: Metal beams, frames, and other structural components can be coated to prevent thermal bridging and condensation, protecting against corrosion and energy loss.

8.Equipment and Machinery: Industrial machinery and equipment can be coated to improve thermal efficiency, protect sensitive components from temperature extremes, and prevent condensation-related damage.

9.Windows and Glazing: Specialized coatings can be applied to window frames and glazing to reduce thermal transfer and prevent condensation, enhancing comfort and energy efficiency.

10.Cold Storage Surfaces: Walls, floors, and ceilings of cold storage facilities and refrigerated trucks can be coated to maintain low temperatures and prevent condensation, ensuring the integrity of stored goods.

11.Concrete Surfaces: Concrete walls and floors, especially in basements and parking garages, can be treated to improve insulation and prevent condensation-related damage.

These surfaces represent a wide range of applications for thermal insulation and anti-condensation coatings, helping to enhance energy efficiency, protect against moisture damage, and improve overall thermal management across various environments.

Surfaces to Apply

1.Walls: Both interior and exterior walls of buildings can benefit from these coatings to improve thermal insulation and prevent condensation, enhancing overall energy efficiency.

2.Ceilings: Applying coatings to ceilings helps reduce heat transfer and prevent condensation, contributing to a more comfortable indoor environment.

3.Roofs: Coatings on roofs help to reflect heat, reduce cooling costs, and prevent condensation, which can lead to leaks and structural damage.

4.Floors: Basements and ground floors can be treated to prevent heat loss and condensation, improving thermal comfort, and protecting against moisture-related issues.

5.Pipes and Ductwork: Coatings applied to pipes and HVAC ductwork help maintain temperature, reduce energy loss, and prevent condensation that can cause water damage.

6.Tanks and Storage Vessels: These surfaces, particularly in industrial settings, benefit from insulation to maintain temperature stability and prevent condensation, which can lead to corrosion.

7.Metal Structures: Metal beams, frames, and other structural components can be coated to prevent thermal bridging and condensation, protecting against corrosion and energy loss.

8.Equipment and Machinery: Industrial machinery and equipment can be coated to improve thermal efficiency, protect sensitive components from temperature extremes, and prevent condensation-related damage.

9.Windows and Glazing: Specialized coatings can be applied to window frames and glazing to reduce thermal transfer and prevent condensation, enhancing comfort and energy efficiency.

10.Cold Storage Surfaces: Walls, floors, and ceilings of cold storage facilities and refrigerated trucks can be coated to maintain low temperatures and prevent condensation, ensuring the integrity of stored goods.

11.Concrete Surfaces: Concrete walls and floors, especially in basements and parking garages, can be treated to improve insulation and prevent condensation-related damage.

These surfaces represent a wide range of applications for thermal insulation and anti-condensation coatings, helping to enhance energy efficiency, protect against moisture damage, and improve overall thermal management across various environments.

Technical Data

1 | Base | Water based acrylic coating |

2 | Container size | 18 litres |

3 | Weight dry | 0.34 kg/m2 at 1mm |

4 | Weight wet | 0.73 kg/litre |

5 | Container wet | 13.14 kg |

6 | Coverage (per litre) | 1.0 m2 at 1.00 mm DFT |

7 | Top coating | Please contact us for more information |

8 | Solid content | 78-80% |

9 | Limitations | Applications should not exceed 185°C. |

10 | Surface temperature | Surface temperatures for applications should be greater than 5°C. |

11 | Method of application | Airless spray, Small spray application, Brush or roll |

Contact Us

OUR LOCATION

647 Melton Road, Unit 7, Thurmaston/Leicester, LE4 8EB

Monday-Friday 9:00-19:00